As it is proven historically, Locomotive Traction Motor Parts are the major contributors to maintenance expenses for railways and locomotive owners worldwide. That is why locomotive traction motors are recognized as a never-ending nightmare among the railways and transportation industry.

Getting over this significant issue demands high-quality products backed with extensive technical knowledge in the field.

Locomotive Traction Motor Manufacturing Capability:

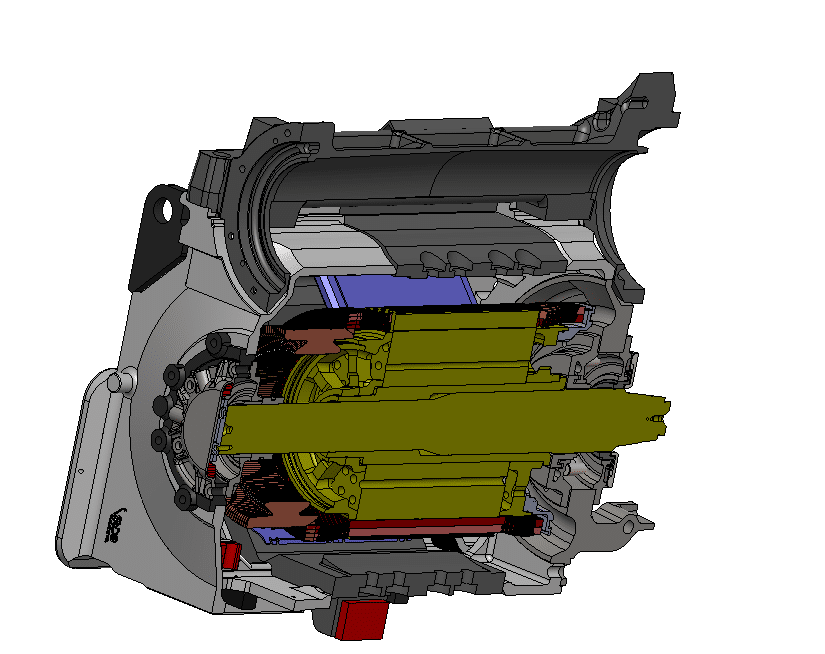

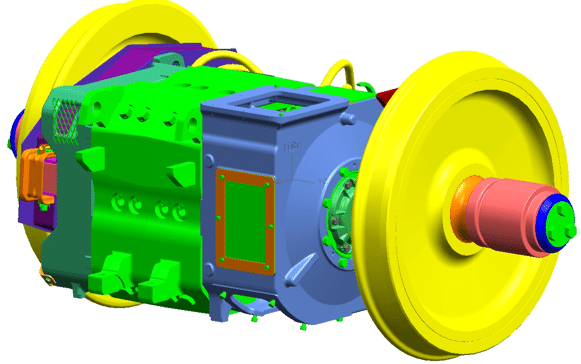

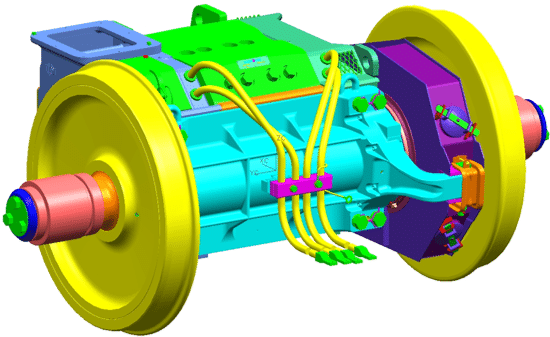

Supco Canada Railway Supply can supply and manufacture brand new traction motors and armatures that interchange with EMD® D77/D78/D87/D90/D100 and D78/D87BTR Traction Motors, and GE® 761/752 AG/AH traction motors.

All traction motors are made in substantial compliance with OEM specifications and used widely by the first-class railway industry. Whether it is for your EMD or GE locomotive, you need a reliable and experienced supplier for all your traction motor spare parts.

Some of our manufacturing and services include:

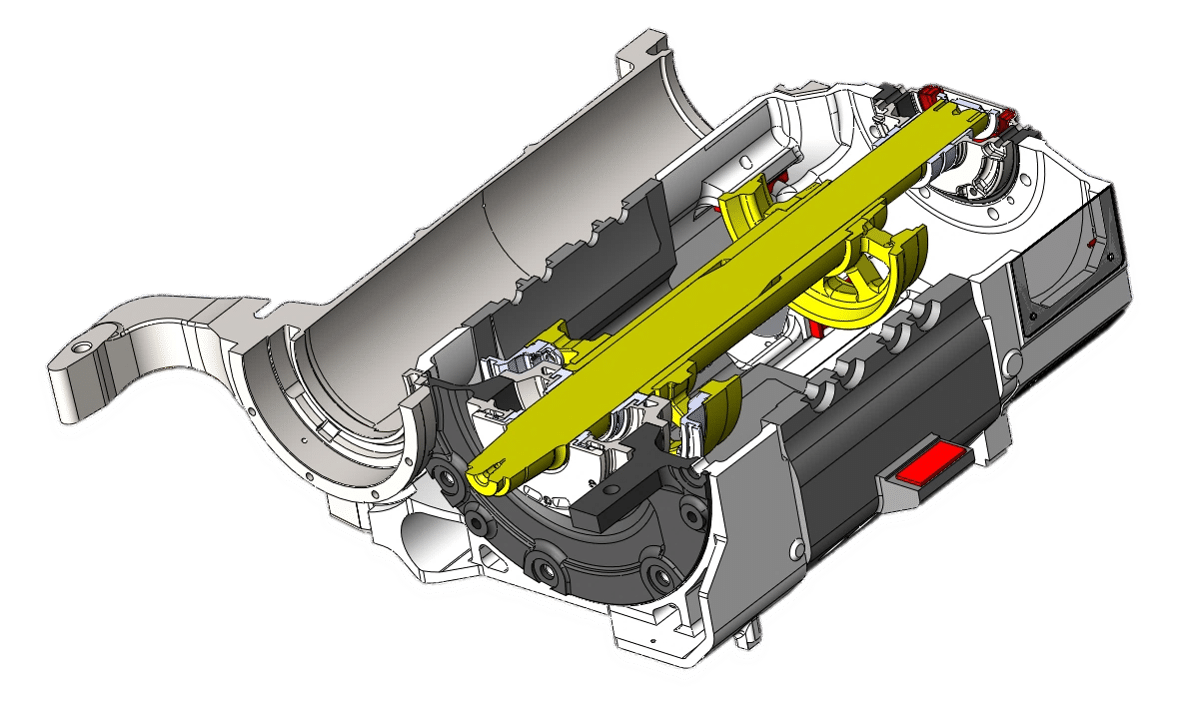

- Fabrication of the Frame – Casting and complete CNC Machining

- Manufacturing the Main and Interpol Coils with Silicone or Mica Technology

- Manufacturing Armature Laminations, Coil Supports, Shafts, Commutators

- The entire winding of the Armature

- Manufacturing all the traction motors’ bearing parts

- Assembly and examine of Traction Motors to OEM Specifications

Supco Canada Railways Supply Group is a quality provider of remanufacturing services for rotating electrical apparatus for Rail and Mass Transit, including Traction Motors. With a combined experience of over half a century, our reputation is equivalent to high-quality products, dependable re-manufacturing services, and excellent customer service.

We standby a perfect practice of professionalism, integrity, and total commitment to our customers’ satisfaction.

We supply high-quality, reliable, and cost-effective locomotive traction motors to our domestic and international clients by utilizing progressive technical methods and efficient manufacturing processes.

We are committed to delivering professional re-manufacturing services, attentiveness to details, responsiveness to customers’ requirements, and flexibility to provide effective and reliable solutions to the transit industry.

Our sales commission is not over by shipping the re-manufactured unit out of the door. Still, we trace the locomotive traction motors and scan them to identify the reasons for failures and provide preventative maintenance solutions and a custom modification to our repair procedure to solve each client’s unique problems.

We have recently published an article. In this article, SUPCO demonstrates the root cause of damages to pinion traction motors and proposes the methods for how to improve them with higher quality and less cost.

We also can re-manufacture DC and AC traction motors, including EMD, GE, AEG, BRUSH, HITACHI, … to OEM specification.

If you are more interested you can read our comprehensive article on comparison AC & DC traction motor called AC vs DC traction motors

Additional Capabilities:

We recognize that a wide variety of locomotive traction motor parts is no longer fully supported by the OEM. We are also aware that OEM-supplied details are remarkably at a high cost due to OEM manufacturers’ overhead expenses.

To help our valued customers, we initiated dedicated technical and precise manufacturing programs to fabricate these components to OEM specifications to ensure the availability of high-quality parts and subassemblies necessary for overhaul or complete re-manufacturing of various traction motors.

By implementing this task over many years in the railway industry re-manufacturing field, we now manufacture a wide range of traction motor parts from OEM replacements to quality that exceeds OEM design.

All types of locomotive traction motor parts meet the OEM specifications and can be customized to your requirements. For a reasonable cost, you can have the hight quality product at the right time. Stay on budget and get your traction motor parts on time.

Contact our experts

Don’t hesitate to contact us!

Examples and Performance Characteristics of some notable locomotive traction motors:

- EMD D77 : D77 model from the famous American manufacturer Electro-Motive Diesel (EMD) is a renowned traction motor. The specifications are listed as:

- Gear ratio = 58 : 19

- Turns per coil = 16

- Rated voltage and current = 550 V and 1065 A

- EMD D78 : EMD’s D78 model is similar to D77 but with differently sized copper conductors for better heat dissipation. The specifications are listed as:

- Gear ratio = 58 : 19

- Turns per coil = 16

- Rated Brakehorspower = 700 HP

- GE 752 : This model is manufactured by the renowned multinational American company General Electric. GE 752 has the following specifications:

- Nominal Horsepower = 750 HP at 1040 RPM

- Rated power = 800 kW

- Rated voltage and current = 750 V and 1150 A

- EMD D87 : The D87 traction motor comes in two variants, i.e., D87 and D87BTR. Both have the following technical specifications:

- Gear ratio = 62:15

- Rated Brakehorspower =83 HP